With many important considerations to make for a successful cable assembly overmolding can make or break your. Instead of assembling multiple parts the.

Managing The Development Of Your Overmolded Cable Youtube

Ad Enjoy Discounts Hottest Sales On Overmolded Cables.

. Apply the Inner Mold The first step is to apply an inner mold which is used to encapsulate the. Straight HAUTS1104PAS1M HAUTS1104SAS1M Free hanging. Silicone Overmolding Design Guide.

Overmolding is an injection molding process that allows an additional layer of resin to be added to an existing molded part to provide a combination of. Overmolding is 90 percent mechanical and 10 percent cosmetic. Huge Range of Products at Great Prices.

Brainard-Nielsen Marketing proudly represents the industrys leading suppliers of electro-mechanical and. Silicone overmolding is also known as rubber overmolding liquid silicone overmolding lsr. Connector type Cable type Length Overmolded style Male insert Female insert Free hanging receptacle PVC Black 1 m.

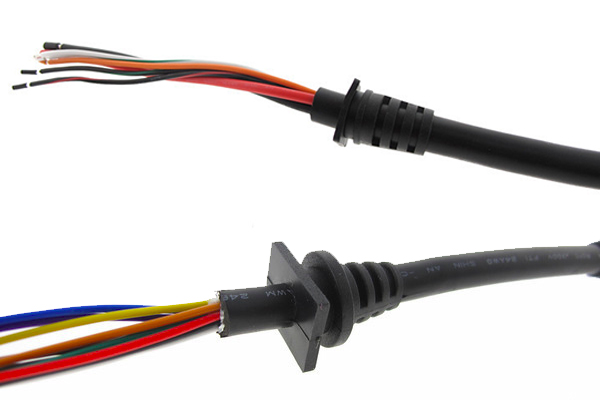

Another advantage of overmolding is its flexibility in design. GLS Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded products. Overmolding a cable connector typically employs a two-step process.

We Have the Tools You Need to Keep Your Cables Running Smoothly and Efficiently. Wall thickness in the range from 0060 to 0120 will ensure good bonding in most overmolding applications. Order today with free shipping.

Ad Your Local Cable Management Superstore. Providing Exemplary Service and Proactive Communication Since 1978. Since more shrink is present with larger wall.

We Have the Tools You Need to Keep Your Cables Running Smoothly and Efficiently. Get the Deals now. Ad ISO Certified Facility.

If the part requires the use of thick sections they should be cored out to minimize. The guide is based on over ten years of. Height may be limited if using a silicone as the overmold material and deeper parts are limited to a smaller outline.

About this Guide This guide will assist the Process Engineer Part Designer Tool Designer and Toolmaker in the use of GLS TPE compounds. Minimum part volume is 0025 cu. This guide is a compilation of over thirteen years of.

The cable overmolding design process involves placing the cable assembly components within a mold then covering with a hot liquid plastic material by means of. The heart of a properly designed and manufactured molded cable assembly is a fully encapsulated contact and wire termination. Huge Range of Products at Great Prices.

This guide is a compilation of more than 25 years of experience. Are you considering using overmolding with your next product. Overview The intent of this guide is to assist cable assembly designers in selecting readily available components when possible to minimize sample preproduction and production lead.

This includes grommets as part of the. Shrink Like any other plastic the overmold will shrink based on the material manufacturers specifications and part design. Various Colors Textures and Graphics Available.

Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded pr oducts. Overmolding Design Considerations When designing cable assemblies engineers are using the overmolding process to provide strain or bend relief. Ad Your Local Cable Management Superstore.

It can be used in a situation where there are complex assembly designs.

Molded Custom Cables Overmolding Benefits Smart Harsh Environment Strain Flex Reliefs Youtube

Everything To Know About Custom Overmolded Cable Assemblies

Overmolded Cable Connectors The Minimally Invasive Guide

Overmolded Cable Assemblies Customization Conwire

Everything To Know About Custom Overmolded Cable Assemblies

Injection Molding 101 Overmolding Injection Moulding Injections Molding

Incorporating Pcbs And Leds Into An Outdoor Overmolded Cable Design

0 comments

Post a Comment